This article features affiliate links, meaning we’ll earn a small commission if you purchase through these links. Please read our Privacy Policy for more details.

Wheelwright From Romanian Village of Straja Explains Wooden Wheel Making Process

Curious to know a wooden wheel making process? My compliments, if you plan to hand craft one by yourself.

I never thought that making a wheel could be so intricate, until I met traditional carpenter Popescu Vasile from the village of Straja, Suceava County. As a child, his father taught him the secrets of making wheels.

He became a wheelwright. At that time, he used to handcraft a whole ox-cart.

In Romania, wooden wheels are still being used in agriculture, on a fountain, for decoration purposes.

This occupation has been passed down from father to son, and from master to apprentice. It’s one of the most important crafts.

Making a cartwheel involves a lot of precision, many parts and many steps for each part: the nave, 12 spokes and 6 felloes. It takes two days of work.

That’s why we couldn’t see all the steps. By the time we arrived, the nave was already done, but mr. Vasile was happy to explain the basics.

The Traditional Craft of Making Wooden Cartwheel by Hand is More Complicated Than You Thought

To begin with, the nave is manually turned on a lathe.

With a chisel, the wheelwright cuts out 12 mortises into the nave, at equal distance from one another, measured with a compass.

Affiliate links Wood Carving Tools for Rotary Tool 5 PCS Woodworking Tools Engraving Drill Bit Set Wood Crafts

Next, the wood artisan decides the length of the spokes without considering the ends of the spoke, which are morticed into the nave and felloe.

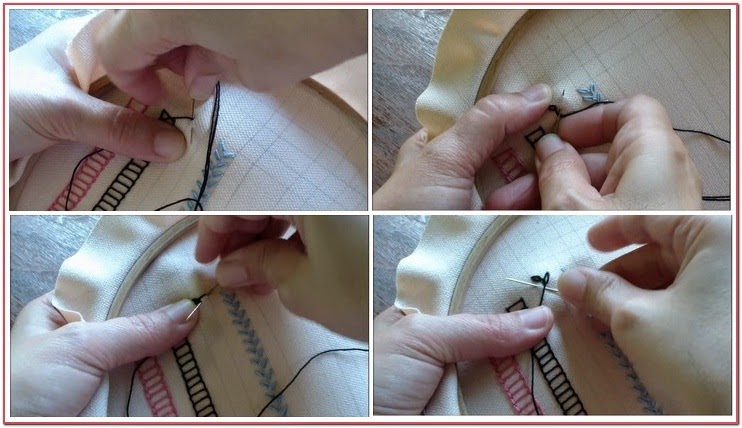

First, the spokes are shaped by axe, saw and a drawknife. Next, they are finished with a spoke shave and sandpaper. Finally, it is finished with a piece of felt.

The spokes are angled to give the right amount of dish. A handcrafted tool is used to check on the angle of the spokes.

Ash is the selected wood for it’s hardness. Elm is also preferred, for being a hard wood, highly resistant under pressure.

Affiliate links Buy Stubai Drawknife Made In Austria

With the axe and saw, the ends of the spokes are shaped to fit into the nave and felloes.

Each felloe is curved to take two spokes. With a gimlet, he cuts two holes in the felloe. A wooden tool tells the exact circumference of the two holes in the felloe, so he measures the end of each spoke with this tool.

Iron hoops are fitted around the circumference of the wheel. The traditional artisan likes to talk about everything wood related: shingles, wood types, properties, when’s the best time for cutting fresh wood.

Read Also

Barrel Making Traditional Artisans – Master Cooper ‘ s Wooden Barrels

Blog Comments

Susan Hesselgesser

November 9, 2022 at 1:26 am

I would like to ask questions about a Mormon cart that I have. It was totally restored 30 years ago.

Bianca

November 10, 2022 at 10:00 am

Hi. Send an e-mail at [email protected]. Gr. Bianca.